-

EASY

Design for free with a simple-to-use interface and share with clients

-

SMART

Real-Time 3D Visualization

Calculates material costs as you go

-

FAST

Compiles cut-ready files automatically

For both table saws and CNC machines

Easel Cabinetmaker

With the easiest cabinet design software you can go from custom cabinet design to production in a few easy steps. Get started for free.

Easel Cabinetmaker

Supported Features

Cabinet Types

Standard wall cabinets

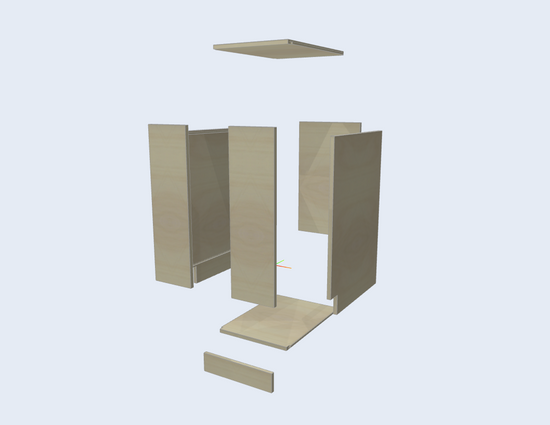

Standard base cabinets

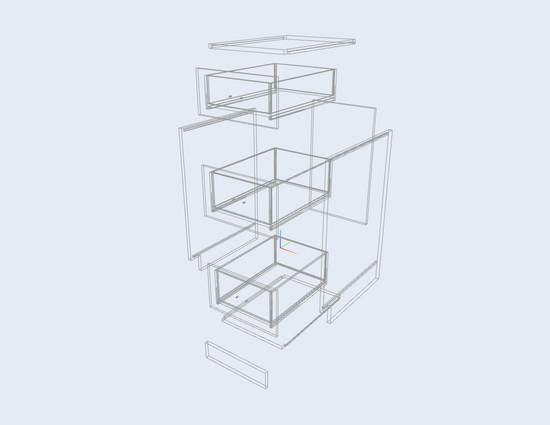

Drawer base cabinets

Sink base cabinets

Blind corner cabinets

90° corner cabinets

Standard Island cabinets

Optional doors, shelves, and drawers

Cabinet Styles

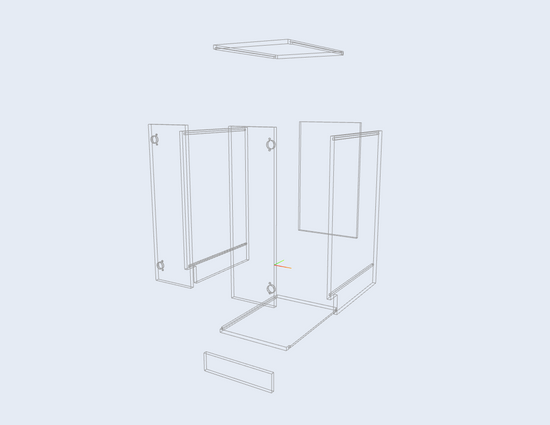

Framed and frameless cabinets

Flat-panel door and drawer fronts

Shaker panel door and drawer fronts

Glass frame door fronts

Inset, full-overlay, and partial-overlay fronts

Construction

Optional integrated toe-kicks

Butt joint and blind-dado box construction

Locking-rabbet drawer construction

Custom door and drawer dimensions

Material selection for box, fronts, backs, shelves, and drawers

False drawer fronts

Optional system 32 drill-holes

Adjustable and fixed shelves

Filler panels

Hardware

Compatibility with supported Blum hardware

Optional holes and cut-outs for easy installation of hardware

Hinges and hinge plates

Drawer slides and locking devices

Door and drawer pulls/knobs

Visualization

Real-time 3D rendering

Individual-cabinet and full-design views

Wireframe and exploded view settings

Image download of 3D scene

Custom cabinet finishes

Custom material finish for pulls and knobs

Manufacturing

Optimized to integrate seamlessly with the 4x4 X-Carve Pro CNC machine

Works directly with other size-appropriate, grbl based CNC machines

Efficient panel optimization and nesting

Automatic cut list generation from designs

Cut lists for table, track, and panel saws

Support for sheet goods and dimensional lumber

Custom stock material dimensions

Detailed Design BOMs

Collaboration & Interaction

Presentation view to share Designs with clients and other collaborators

Commenting in Designs for asynchronous collaboration

Make updates to shared Designs in real time

Business Tools

Job tracking and project management tools

Save notes, checklists, and images for each job

Integrated cost and profit estimation

Connect with other Cabinetmakers and stay up to date with new releases through the Easel Cabinetmaker forum!

Easel Cabinetmaker Plans & Pricing

Easel Cabinetmaker + X-Carve Pro CNC

One platform to scale your cabinetmaking business

Collapsible content

Generate manufacturing estimates

Software automatically estimates cutting times for each job

Professional results without the learning curve

World class customer success team to help with sales questions, onboarding and setup, and technical troubleshooting

1-year limited warranty included with every X-Carve Pro CNC machine purchase with option to add 3 year extended protection plan

Priority support includes virtual training and troubleshooting as needed

Machine ships with factory calibrated, fully assembled X-Axis gantry - only minimal assembly is required.

You'll be up and running within 2-3 hours of receiving your new X-Carve Pro CNC machine and cutting real parts on day 1

Safer operations with integrated dust control

Hands-free cutting

Dust collection bundle included in your CNC machine purchase

Flexibility in design and edits

Design change requests from clients can be done quickly in the software and flow through to your cutting files automatically

Reduced material waste

Minimize material loss with layout control of nested parts in your cutting files

Accurate, high-quality cuts

Minimize costly errors with cutting accuracy down to .001 inches